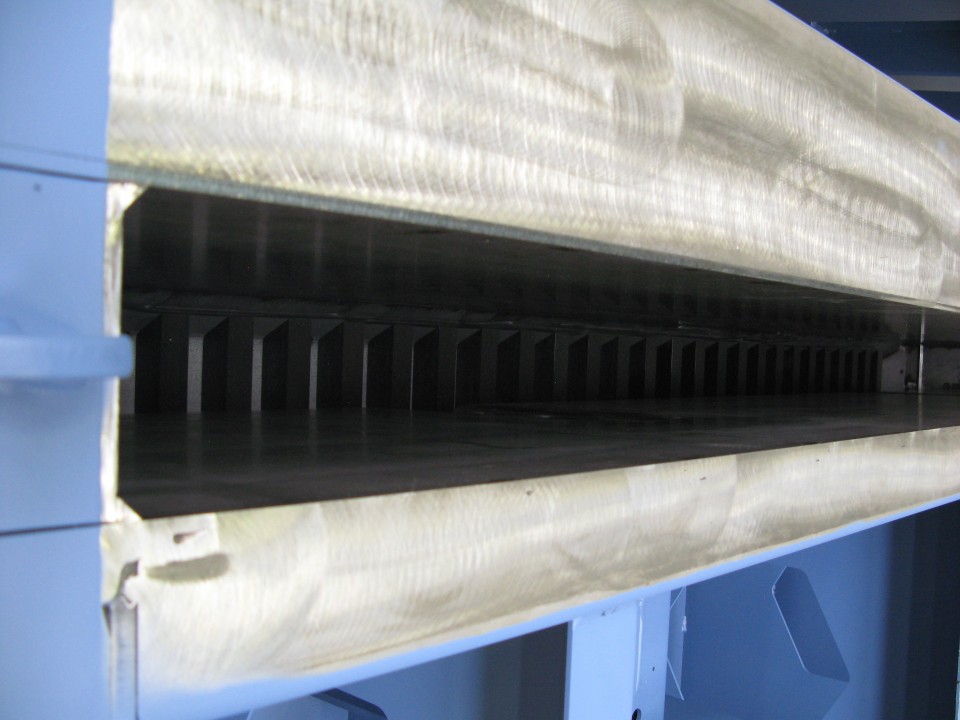

For the production of innovative noise-reducing elements, we constructed various steel moulds for our client.

They include these two. The product can be poured in one stage and can be released by removing the floating core and folding away the hinged walls.

The mould is has unique plastic profiles that give the fronts of the sound barrier an absorbing effect. The screens consist of two parts with substructures made of concrete. On top of this substructure a diffractor gives the screen its specific sound deflecting effect.

+31 (0) 38 444 28 55

+31 (0) 38 444 28 55